|

|

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Astra Tech implant system

Developed with a biological and biomechanical approach.

language |

l |

THAI |

|

|

To put it simply, with the Astra Tech implant system, esthetics are integrated into the implant system design.

We work together with nature in supporting the natural healing process instead of interfering with it. That is why you can rely on the Astra Tech implant system,

not only today, but also tomorrow and beyond. |

|

|

|

OsseoSpeed™ more bone more rapidly |

|

|

MicroThread™ biomechanical bone stimulation |

|

|

The Conical Seal Design™ is a conical connection below the marginal bone level that transfers the load deeper down in the bone. Compared to conical connections above the marginal bone level and flat-to-flat designs, Conical Seal Design reduces peak stresses and thereby preserves the marginal bone. It also seals off the interior of the implant from surrounding tissues, minimizing micro-movements and micro-leakage. Conical Seal Design simplifies maintenance and ensures reliability in all clinical situations. Whats more, the tight and precisely fitting implant-abutment relation of the Conical Seal Design makes abutment connection a quick and simple procedure. The abutment is self-guiding and the installation procedure is non-traumatic, eliminating the risk of bone damage. |

|

|

Connective Contour™ increased soft tissue contact zone and volume |

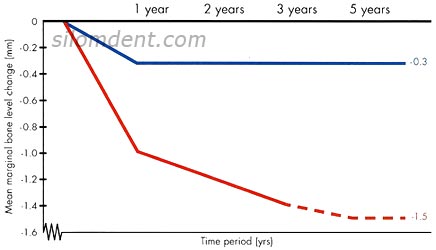

Marginal bone maintenance with Astra Tech Implant System™

With our strong focus on research, science and documentation, we have followed the maintenance of the marginal bone level on our own system

for many years and noted that the marginal bone levels around Astra Tech implants have been extraordinarily well maintained.

When compairing our exceptional result to the current standard norm, it turns out that there is a large gap between what can be achieved

with the Astra Tech Implant System and what is currentry accepted as a successful treatment result.

![]()

Astra Tech Implant System™ level |

Standard norm |

Atlantis™ patient-specific abutments < < click for details

Cresco™ perfect fit every time < < click for details

HOME

l SERVICE

l DENTISTS

l TECHNOLOGY

l FACILITIES

l ABOUT US

l SITE MAP

PROMOTION

l PRICE&DURATION

l CONSULTATION

l FAQ

l LINKS

l MAP

l TESTIMONIALS

l OUR LAB

l RESOURCES

DENTAL BRACES

l LASER TEETH WHITENING

l IMPLANT DENTISTRY

l ENDODONTICS

l OPERATIVE DENTISTRY

l SEDATION DENTISTRY

COSMETIC DENTISTRY

l PROSTHODONTICS

l PERIODONTICS

l ORAL SURGERY

l PAEDODONTICS

l GP & ORAL EXAM

l OCCLUSION

DENTAL OFFICE

l DENTAL CLINIC

l COSMETIC DENTISTRY

l COSMETIC DENTIST

l TEETH BLEACHING

l TOOTH WHITENING

DENTAL CROWNS

l DENTAL IMPLANTS

l DENTAL TREATMENT

l DENTAL IMPLANT

............................................................................................................................. Copyright© 2004 SILOM DENTAL BUILDING. All Rights Reserved.

Local Call : 0 2636 9092-5, International Call : (+) 66 2636 9091, (+) 66 2636 9097

e-mail :silomdental@silomdental.com

Dental Implant, Dental Implants, Implant, Dental Implant Bangkok, Dental Implants Thailand, Implant Dental Center, Implant Bangkok Thailand